DeepFleet, Amazon's new AI model, optimizes the operation of entire robot fleets. It coordinates robot movement within the order fulfillment network, improving transit time by 10% and supporting faster deliveries at lower costs. This AI model acts like an intelligent traffic management system, directing robots in the complex warehouse environment. This reduces congestion, optimizes routes, and processes orders more quickly. The technology is built on Amazon’s vast inventory activity data and AWS tools like Amazon SageMaker.

"DeepFleet not only improves operational performance, but also brings goods closer to customers, thereby shortening delivery times and saving costs," an Amazon representative said. "Because it is developed on a continuously learning AI platform, DeepFleet will increasingly optimize how robots coordinate."

DeepFleet is considered a practical AI approach by Amazon – focusing on solving real-world problems rather than developing technology for its own sake. The 10% reduction in robot travel time offers concrete benefits: faster deliveries, lower operating costs, and energy savings. According to Amazon, this is just the beginning. As DeepFleet receives more data, the system will become increasingly intelligent, enabling deeper optimization, expanding the ability to bring goods closer to customers, and continuing to reshape the future of robotic logistics.

|

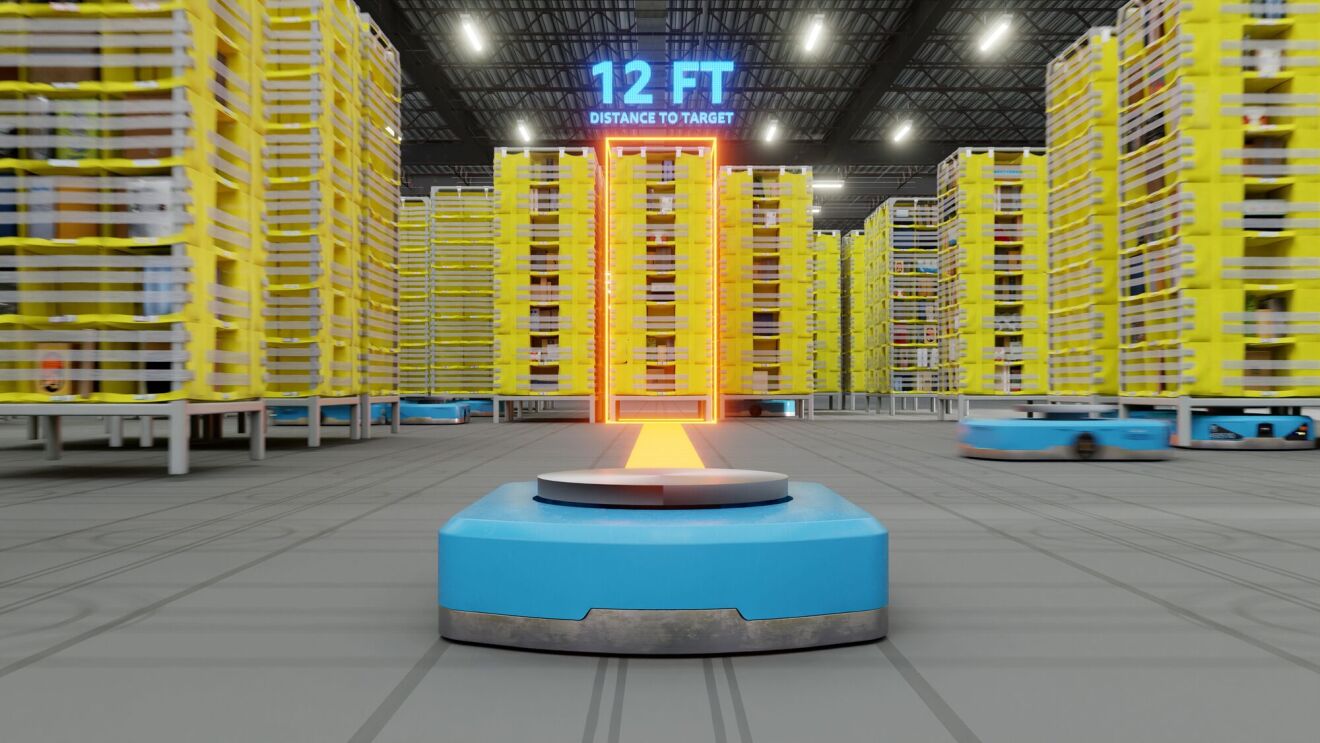

DeepFleet – Amazon’s new AI platform optimizes robot movement in warehouses. Photo: Amazon |

DeepFleet – Amazon’s new AI platform optimizes robot movement in warehouses. Photo: Amazon

Along with the launch of the new AI model, Amazon also marked two milestones in its journey of robotics and AI development. The company deployed its one-millionth robot, solidifying its position as the world’s largest producer and operator of mobile robots. This robot was introduced at a fulfillment center in Japan, joining a network of over 300 Amazon facilities worldwide.

The one-millionth robot milestone and DeepFleet's launch suggest a future where robots and AI combine to redefine logistics. 12 years ago, Amazon began with a simple question: how to get employees to access goods faster. Now, AI is being applied to make entire robot fleets more intelligent, thereby enhancing customer value with faster service and lower costs.

Amazon’s robotics and AI strategy is distinguished by its combination of innovation and practical impact. The robots are manufactured in the US with the participation of local suppliers and then deployed globally. This model ensures quality standards while creating a continuous feedback loop between the design team, manufacturing, and frontline operations staff.

|

Robots can handle heavy goods, accelerating order processing. Photo: Amazon |

Robots can handle heavy goods, accelerating order processing. Photo: Amazon

Amazon began its robotics journey in 2012 with its first model capable of moving shelves in warehouses. Today, the company has various robot types: Hercules, which lifts and moves up to 567 kg of goods; Pegasus, which uses a precise conveyor belt to handle individual packages; and Proteus, the first fully autonomous mobile robot, capable of moving safely around employees in open areas while transporting heavy carts.

These robots work alongside employees, handling heavy lifting and repetitive tasks, while workers have the opportunity to develop technical skills. Since 2019, over 700,000 employees have received advanced skills training, many of which involve advanced robotic technology. At the new-generation fulfillment center in Shreveport, Louisiana, which launched last year, the application of modern robots increased the demand for personnel in technical roles by 30%.

Robot technology not only helps move goods but also improves workplace safety and opens up new career opportunities. Through the Amazon Career Choice program, which provides upfront tuition assistance for frontline employees, workers can access the skills needed for technical jobs in systems operations and other high-demand fields.

Hai My (Following Amazon)