ATAD Steel Structure Joint Stock Company was recently honored with the "Vietnam Excellence Award - Steel" at the Manufacturing Asia Awards 2025 ceremony, held at the Marina Bay Sands Convention and Exhibition Center in Singapore. The award acknowledges the company's ability to uphold international standards, operate a comprehensive quality management system, and implement a sustainable development strategy (ESG) across its entire design, production, and installation operations.

Speaking at the awards ceremony, Nguyen Le Anh Tuan, general director of ATAD, stated that this award is a recognition of the company's reputation and capabilities in the international market. He noted it marks over two decades of innovation, human value enhancement, and sustainable development.

"We will continue to invest in technology, develop modern, green factory models, and create international-standard projects, thereby affirming the role of Vietnamese enterprises on the steel structure map of Asia and the world", he said.

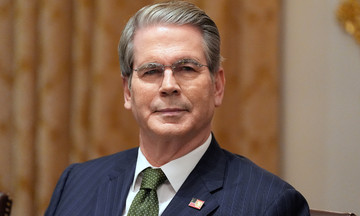

|

Nguyen Le Anh Tuan, general director of ATAD Steel Structure Joint Stock Company, accepted the award on behalf of the company. Photo: ATAD Company |

ATAD operates a LEED Gold certified steel structure factory and holds a range of international certifications, including ISO 9001, ISO 14001, ISO 45001, IAS AC472, CE Marking, AISC, ASME, CWB, and UKCA. These certifications enable the company to meet stringent export requirements for high-standard markets such as the US, EU, UK, Australia, and Japan. ATAD is also a leading company in the steel structure sector, having achieved the "National Brand" title and the "National Quality" Gold award.

The company has developed a modern production model leveraging automation, welding robots, and digital management platforms throughout its design, production, and installation chain. The implementation of SAP ERP, SPM, and a real-time monitoring system standardizes processes, enhancing operational efficiency and quality control. This synchronized digitalization significantly improves deployment capabilities, shortens production times, and minimizes errors, allowing the company to handle projects of large scale and complexity.

With an annual production capacity of 216,000 tons of steel structures, ATAD provides comprehensive services from design, fabrication, and transportation to installation and maintenance. The company currently operates 13 offices domestically and internationally, executing projects in over 60 countries for major clients like Samsung, Heineken, Hyundai, Toyota, P&G, Sanofi, VinFast, and Hoa Phat.

|

ATAD Dong Nai is one of the first LEED Gold certified steel structure factories in Asia, with a LEED Platinum certified factory office. Photo: ATAD Company |

Furthermore, ATAD is a pioneer in implementing a "Zero Accident" policy and applying LEED standards (Leadership in Energy and Environmental Design, developed by the US Green Building Council) to reduce carbon emissions. The company also maintains long-term corporate social responsibility (CSR) programs focused on education, healthcare, and community development. These activities are integrated into its ESG strategy, aiming for efficient operations, risk reduction, and sustainable growth.

To maintain high standards in quality, safety, and sustainability, ATAD operates a Smart Factory model and utilizes digital platforms such as 3D BIM, Tekla Structures, and Lean Manufacturing. These tools optimize design, control progress, and enhance accuracy at every stage. Concurrently, the company implements energy-saving solutions and environmentally friendly operating procedures, which help reduce emissions and improve resource utilization across the entire production and installation chain.

ATAD's technical capabilities were prominently showcased at the Long Thanh International Airport project, where it produced and installed over 45,000 tons of steel structures. A significant achievement was the 5,300-ton central roof lifting using specialized roof-lifting technology, marking a milestone in complex steel structure construction. The company has also participated in other major projects in Vietnam, including Ho Chi Minh City Metro Line 1, the Vietnam Exhibition Center (VEC), and the Hoa Phat Dung Quat Steel Complex.

|

ATAD performed the 5,300-ton central roof lifting using roof-lifting technology at the national key project – Long Thanh International Airport. Photo: ATAD Company |

The Manufacturing Asia Awards, organized by the industry platform Manufacturing Asia, recognize outstanding enterprises and projects in the manufacturing sector across the Asia-Pacific region. The program brings together manufacturing companies and solution providers, evaluating them based on criteria such as innovation, operational efficiency, market impact, and scalability.

With diverse categories spanning operations, safety, productivity, R&D, digital transformation, and sustainable development, the Manufacturing Asia Awards provide a significant platform. It allows businesses to affirm their position, enhance their reputation, and connect with the manufacturing community in the region.

Hai My