SCG's plants in Saraburi have replaced a portion of fossil fuels with refuse-derived fuel (RDF) and biomass. As a result, approximately 641,000 tons of biomass are used annually, avoiding up to 774,600 tons of CO2 emissions. In addition, 261,000 tons of RDF are also incinerated instead of traditional fuels, equivalent to a further reduction of 381,000 tons of CO2.

A company representative stated that this shift reduces environmental burden and significantly contributes to the carbon neutrality goals of the province and the cement industry. This is also a prominent result of SCG's ESG 4 Plus strategy. This strategy focuses on five pillars: Set Net Zero, Go Green, Reduce Inequality, Embrace Collaboration, and ensure Fairness and Transparency in all operations.

|

The company's cement plant in Saraburi province, Thailand. Photo: SCG |

The company's cement plant in Saraburi province, Thailand. Photo: SCG

Saraburi province is located in central Thailand, about 100 km northeast of Bangkok. The area is considered a cement industry hub, with a production capacity accounting for about 80% of the nation's total. Due to the high concentration of production, Saraburi generates substantial emissions. According to 2019 data, total greenhouse gas emissions in the province reached 22.1 million tons of CO2, with the majority coming from industrial processes and product use (IPPU), accounting for over 67%. This is followed by energy, transportation, and agriculture and waste.

With Thailand committed to reducing emissions by 40% by 2030 and achieving carbon neutrality by 2050, high-emission areas like Saraburi play a crucial role. The provincial government has set a target of reducing 5 million tons of CO2 by 2027. Of this, 3.5 million tons will come from green industry and products, 1.47 million tons from energy, and 0.01 million tons each from agriculture and waste.

To achieve this goal, the province is developing a "Low Carbon City" sandbox model with 5+1 pillars, implemented in collaboration with the government, the private sector, the Thai Cement Manufacturers Association (TCMA), and the local community. The main pillar is the conversion of waste into raw materials or alternative energy. Utilizing waste in this way reduces the burden on the environment, supports the development of a circular economy, and promotes sustainable production models.

|

The Saraburi Low Carbon City model and SCG's waste recycling solution presented at the "Green Trade Forum 2025". Photo: SCG |

The Saraburi Low Carbon City model and SCG's waste recycling solution presented at the "Green Trade Forum 2025". Photo: SCG

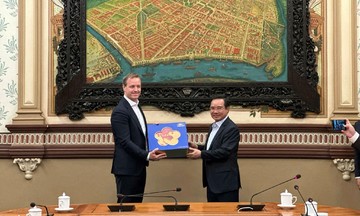

SCG presented its waste recycling solution, which contributes to building a circular economy in the "Low Carbon City Saraburi", at the "Green Trade Forum 2025" organized by the Sai Gon Giai Phong Newspaper in collaboration with the Ho Chi Minh City People's Committee.

This is a prime example of realizing a circular economy through the ESG 4 Plus strategy. In Vietnam, SCG is actively collaborating with management agencies, local authorities, and stakeholders to develop new lifecycles for waste. The corporation has signed a public-private partnership memorandum of understanding with the Ministry of Natural Resources and Environment and companies like Dow Vietnam and Unilever Vietnam. The goal is to build a circular economy model for plastic waste management.

For three consecutive years (2022, 2023, and 2024), SCG participated in the Vietnam Circular Economy Forum chaired by the Ministry of Natural Resources and Environment—now the Ministry of Agriculture and Environment. Through this, the company contributes to promoting the implementation of the National Action Plan for Circular Economy (NAPCE).

Locally, SCG actively cooperates with the authorities of Vung Tau City (former) and related units to implement waste sorting projects at the source, contributing to improving waste management efficiency and promoting sustainable consumption habits in the community. The corporation also regularly publishes sustainability reports, assesses product lifecycles, and implements waste management models at the source.

In addition to environmental initiatives, SCG's member units in Vietnam are also promoting green production through the application of renewable energy and sustainable technologies. Many factories are switching to biomass, installing waste heat recovery systems, and solar roof systems to reduce carbon emissions. The corporation is also developing a range of green products such as low-carbon cement, environmentally friendly packaging, and sustainable plastic pipes.

According to an SCG representative, Vietnam is aiming for Net Zero. SCG desires to be a long-term partner, not only providing green products but also co-creating practical models and solutions for the community and the economy.

Hoang Dan