Nguyen Xuan Phu, Chairman of the Board of Directors of Sunhouse Group, announced this information at Sunhouse's 25th-anniversary celebration held in Hanoi on 26/6. Accordingly, in the next 25 years, Sunhouse aims to become a global home appliance technology group, exporting products that not only meet basic needs but also prioritize health, convenience, and durability for domestic and international users.

|

Nguyen Xuan Phu, Chairman of Sunhouse Group, speaks at the group's 25th-anniversary celebration. Photo: Sunhouse |

Nguyen Xuan Phu, Chairman of Sunhouse Group, speaks at the group's 25th-anniversary celebration. Photo: Sunhouse

To realize these goals, Sunhouse aims to be positioned as a national brand with international standards, establishing a strategic milestone to become the region's number 1 OEM destination (manufacturing from components to finished products based on designs, technical standards, and quality requirements from international partners). Currently, the group is cooperating with over 100 OEM partners worldwide.

According to Mr. Phu, the strategy of boosting exports and becoming the region's leading OEM destination is a key step in Sunhouse's transformation after 25 years of development. Sunhouse aims to own its intellectual property and design language while expanding cooperation with international research centers, institutes, and domestic universities to develop product concepts that meet global market standards and achieve international certifications.

In addition, the company sets an export target of 3,000 billion VND for 2025, aiming to increase the proportion of international revenue by 2030, continuing to expand the market and consolidate its position in the global supply chain. Currently, Sunhouse products are available in more than 20 international markets, including the US, Canada, Japan, South Korea, Mexico, Indonesia, and Malaysia.

|

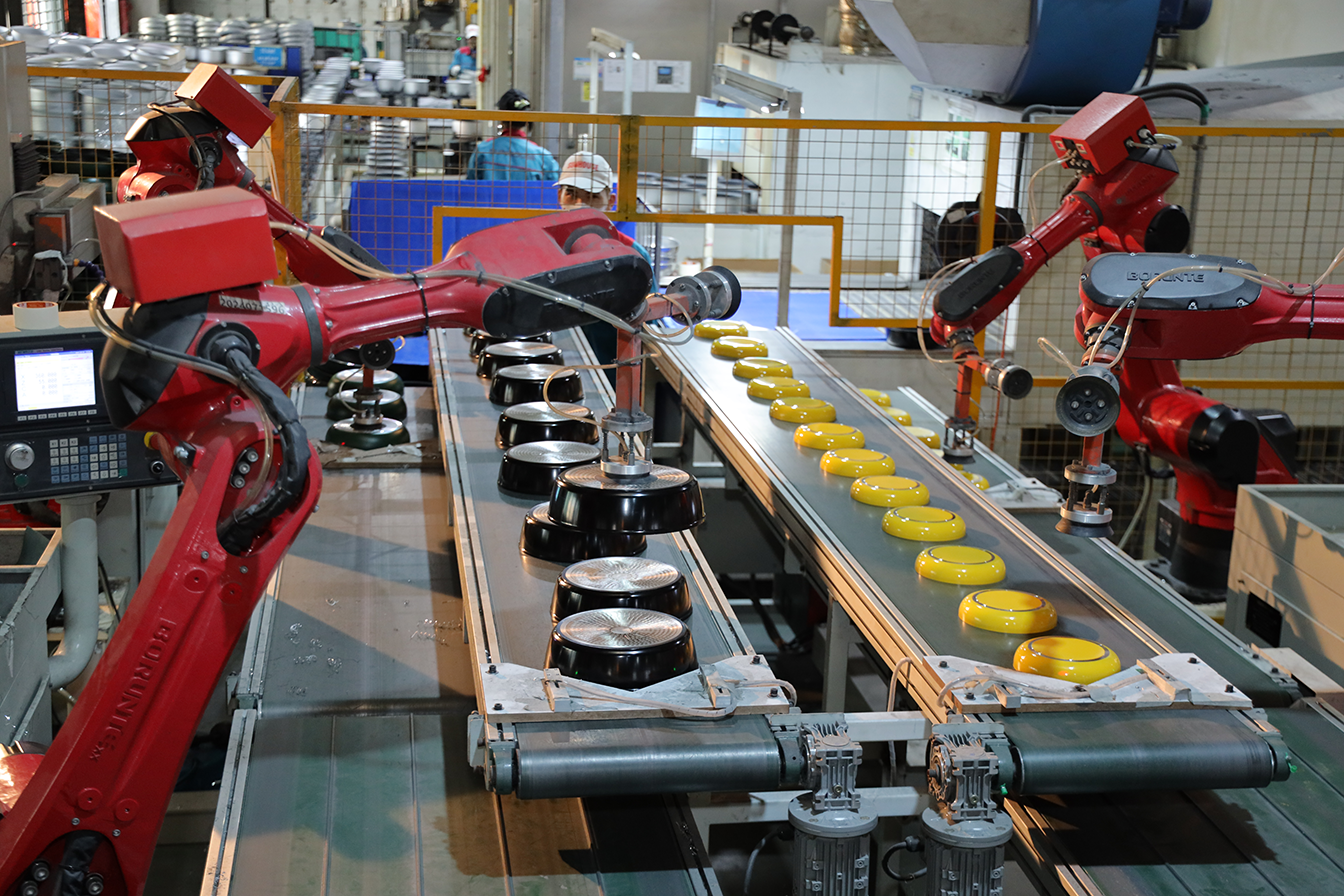

Electrical appliance production line at the |

Electrical appliance production line at the Sunhouse factory. Photo: Sunhouse

Besides its production capacity, the company is currently boosting investment in research and development, applying core technologies to meet domestic and international needs. Sunhouse has a system of 10 factories covering over 100,000 m2, applying automation technology, with a production capacity of over 80 million products annually. Advanced production lines such as automatic painting, impact bonding technology for bottom welding, and full induction pressing help the company master core technologies.

Among them, the Sunhouse Technologies factory is built to the standards of a tier-1 supplier for major electronics corporations like LG and Samsung. The factory has 10 SMT lines imported from South Korea, capable of producing two million electronic components monthly.

|

Sunhouse factory. Photo: Sunhouse |

Sunhouse factory. Photo: Sunhouse

Established in 2000, Sunhouse is a leading group in the field of home appliances, electrical appliances, and kitchen equipment in Vietnam, with over 60,000 points of sale and serving over 20 million Vietnamese families. Starting with a non-stick coating production line imported from South Korea, the group has now expanded its production scale, mastering technology in the household goods sector: from non-stick aluminum, stainless steel, anodized aluminum, plastic, electrical appliances to kitchen equipment, electronics, and refrigeration.

The group sells about 30 million products annually, of which over 13 million are exported. Key products such as non-stick pans, air fryers, and LED lights are popular in international markets such as the US, Japan, Canada, Mexico, and South Korea.

Van Ha