Toto's new three-story, 365,000-square-foot Morrow factory will increase premium one-piece toilet production capacity by 150%, according to an August 22nd announcement. The company plans to shift a significant portion of its operations from Asia to North America, reducing lead times and supporting long-term sustainability goals.

|

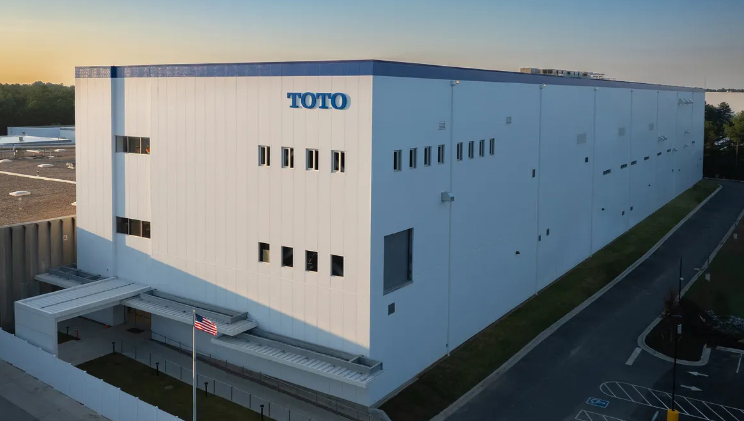

Toto's new state-of-the-art production facility in Morrow, Georgia. Photo: Toto |

Toto's new state-of-the-art production facility in Morrow, Georgia. Photo: Toto

"This investment reinforces our leadership in premium plumbing products and creates a more flexible and sustainable manufacturing network," said Taro Muroi, CEO of Toto USA.

The expanded local production is expected to shorten time-to-market, reduce shipping distances, enable faster deliveries, and lower carbon emissions from logistics.

Nearly half of the Morrow factory is dedicated to producing around 300,000 one-piece toilets annually—a strategic product line in North America. When it opens this fall, the new factory will bring total regional capacity to about one million units per year, including facilities in Morrow, Lakewood (Georgia), and Mexico.

The facility employs 420 local workers and features high-pressure casting systems for larger, more complex toilet designs, expanding Toto's premium product offerings in North America.

Toto is also implementing digital technology to improve operational efficiency. Heat-resistant QR codes on each product allow for real-time tracking, quality control, and data analysis to optimize production processes.

The Dan (according to Supply Chain Dive)