The Vietnam Exhibition Center (VEC) is currently hosting the "80 Years of Independence - Freedom - Happiness" exhibition, featuring 34 provinces and cities, 28 ministries and sectors, with over 230 booths from 106 businesses.

|

The Vietnam Exhibition Center, distinguished by its Kim Quy dome, is currently hosting the "80 Years of Independence - Freedom - Happiness" exhibition. Photo: Vingroup |

The Vietnam Exhibition Center, distinguished by its Kim Quy dome, is currently hosting the "80 Years of Independence - Freedom - Happiness" exhibition. Photo: Vingroup

Among the visitors, Truong Xuan Co, Director of Business Development and Projects at Dai Dung Group, the contractor for the Kim Quy exhibition hall dome—the heart of VEC—recalled the 300-day journey that "kept over 1,000 engineers and workers working day and night."

VEC, invested by Vingroup and covering over 90 hectares in Dong Anh commune (Hanoi), broke ground on 30/8 last year. It ranks among the world's top 10 largest exhibition centers. The centerpiece, inspired by the mythical Kim Quy turtle that built Co Loa citadel, presented both a significant highlight and the greatest challenge.

The 24,000-ton steel dome has a diameter of 360 m, covering an area of over 10 hectares, equivalent to about 14 FIFA soccer fields. The dome's peak reaches 57 m in height. This Grade I structure features a dome-shaped roof covered with a large-span membrane. The investor allowed only a few millimeters of error margin.

As the first person from Dai Dung to examine the project blueprints, Co described it as "a difficult case." Typically, the design phase alone would take a year. Initially planned for a two-year construction period, the project timeline was condensed to 10 months to coincide with the 80th National Day celebrations. The investor invited numerous contractors to propose solutions.

Trinh Tien Dung, Chairman of the Board and General Director of Dai Dung Group, personally presented the chosen solution to the investor. Based on the initial architectural documents from Vin Design Institute, which included the building's functional layout and dimensional outline, Dai Dung proposed a comprehensive plan encompassing design, procurement, fabrication, and erection, all while meeting the deadline of 30/7/2025.

"Tackling difficult tasks is exciting, and this isn't our first encounter with challenging large-scale projects," Dung stated. Dai Dung's design impressed the investor, leading to the 100% domestically-owned company being awarded 71% of the steel structure work, nearly 15,000 tons for fabrication and erection.

|

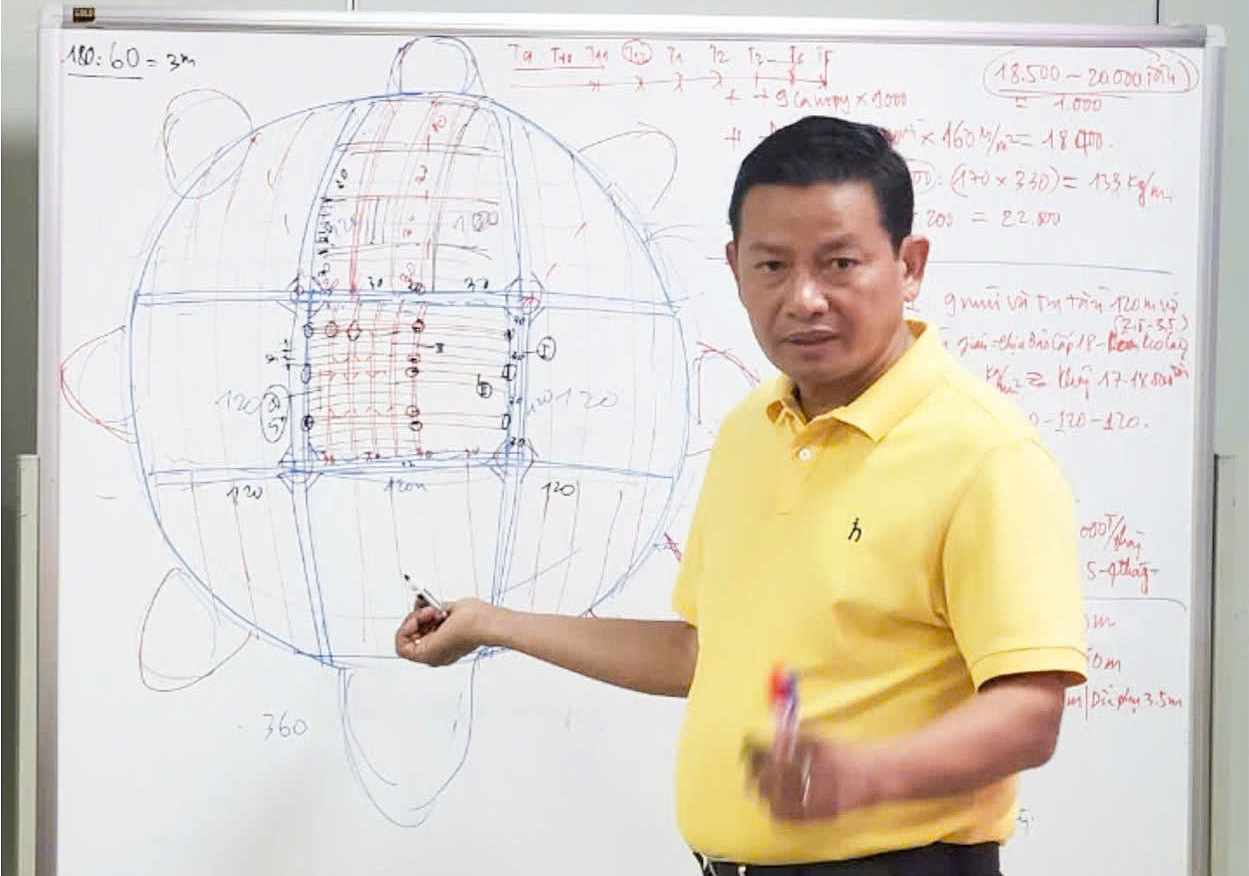

Trinh Tien Dung, Chairman of the Board and General Director of Dai Dung Group, in a meeting discussing the design of the Kim Quy exhibition hall dome. Photo: Hieu Giang |

Trinh Tien Dung, Chairman of the Board and General Director of Dai Dung Group, in a meeting discussing the design of the Kim Quy exhibition hall dome. Photo: Hieu Giang

Once selected, Dai Dung's engineers began detailed design work. Two weeks into the project, Typhoon Yagi struck. Following the typhoon, the investor doubled the safety factor requirements, necessitating design revisions and recalculations. The investor also made three architectural adjustments within 1.5 months, requiring the contractor to quickly adapt.

Hundreds of engineers worked around the clock, using advanced 3D modeling software to simulate the structure and continuously calculate load-bearing capacity, deflection, resistance to level-12 typhoons and level-7 earthquakes, and resilience against harsh weather.

"Teams worked on separate sections and then assembled them. We held nightly meetings with Vin Design Institute to determine the best approach," Co recalled. The overarching goal was to ensure maximum safety for the massive steel dome, minimize maintenance, and extend the structure's lifespan for decades.

According to Trinh Tien Dung, every decision had to meet stringent safety standards, as the dome was the most critical component. Even a minor error could delay the entire project.

While the technical design was complex, meeting the deadline presented an immense pressure. Once the design and construction methods were approved, a comprehensive plan was immediately implemented. Dai Dung's factories across the country divided the workload based on their specialties and transported components to the site. Technical and supervisory teams were stationed from Hanoi to Ho Chi Minh City, ready to address any changes.

Construction progressed outward from the central columns to the surrounding ring columns. Dai Dung deployed some of the largest cranes available, ranging from 300 to 500 tons, to assemble the massive components.

"We worked through holidays and Tet. The site operated day and night," Co recounted. Approximately 1,000 skilled engineers and workers, divided into three shifts, worked 24/7, pausing only during excessively strong winds. 3D laser scanning technology was continuously employed to detect even millimeter deviations for immediate correction. Within about 5 months, 95% of the work was completed, ensuring the project met its deadline.

|

The dome of the National Exhibition Center. Photo: Giang Huy |

The dome of the National Exhibition Center. Photo: Giang Huy

According to Trinh Tien Dung, with over 30 years in the mechanical engineering industry, those involved in the Kim Quy exhibition hall take pride in three achievements: a world-class steel dome structure built by Vietnamese engineers, using entirely domestically produced steel, completed in record time.

"We're experienced in fast-tracked projects, and the Kim Quy exhibition hall dome is not an exception," Dung explained. In 2017, Dai Dung bid for the Lusail Stadium project in Qatar for the 2022 World Cup but was unsuccessful. The Turkish company that won the bid encountered technical and quality issues.

Following the setback, the investor invited Dai Dung and a Chinese company to reconsider. The challenge now was the extremely tight deadline. However, the Vietnamese company demonstrated its capabilities and presented an optimal solution. Outperforming the competition, Dai Dung supplied 6,000 tons of steel for Lusail Stadium and all 28,000 tons for Ras Abu Aboud Stadium (Stadium 974) within a year. Stadium 974, a prefabricated, weld-free structure with a 2 mm tolerance, was designed for disassembly and donation to an African country after the 2022 World Cup, creating two separate stadiums.

According to Dung, the successful completion of these two projects, along with three decades of experience, has propelled Dai Dung onto the global stage, enabling the company to secure complex projects against international competition.

Dai Dung's notable projects include offshore wind power in Taiwan, the Fehmarn Belt Fixed Link tunnel connecting Germany and Denmark, a crude oil pipeline in Tanzania, the Powerhouse Parramatta museum in Australia, and many others, showcasing Vietnamese expertise worldwide. Domestically, the company is involved in various projects at Long Thanh International Airport and recently signed an agreement to construct a pedestrian bridge across the Saigon River.

Dai Dung is currently one of the few companies handling the entire value chain from design, production, transportation, and erection. The group operates six factory clusters on nearly 100 hectares, with an annual capacity of 500,000 tons, over 4,000 employees, including almost 1,000 engineers, utilizing advanced technologies.

"Overcoming seemingly impossible challenges opens up new opportunities for growth and breakthroughs," Dung concluded.

Le Tuyet