A study conducted at Graz University of Technology (TU Graz) in Austria compared the performance of a conventional aluminum beam underfloor battery casing with three different wood-steel hybrid versions. The research team wanted to determine if they could create a more environmentally friendly battery casing without compromising strength.

These hybrid material beams utilize a core of sustainable birch or balsa wood coated with thin, lightweight steel, giving them a much smaller ecological footprint than aluminum, which is energy-intensive to produce.

In a crash test simulating a vehicle or component striking a round steel obstacle at high speed, the Bio!Lib battery casing yielded nearly identical penetration values to the aluminum casing of a Tesla Model S, thanks to the wood's porous cellular structure, which absorbs significant energy.

|

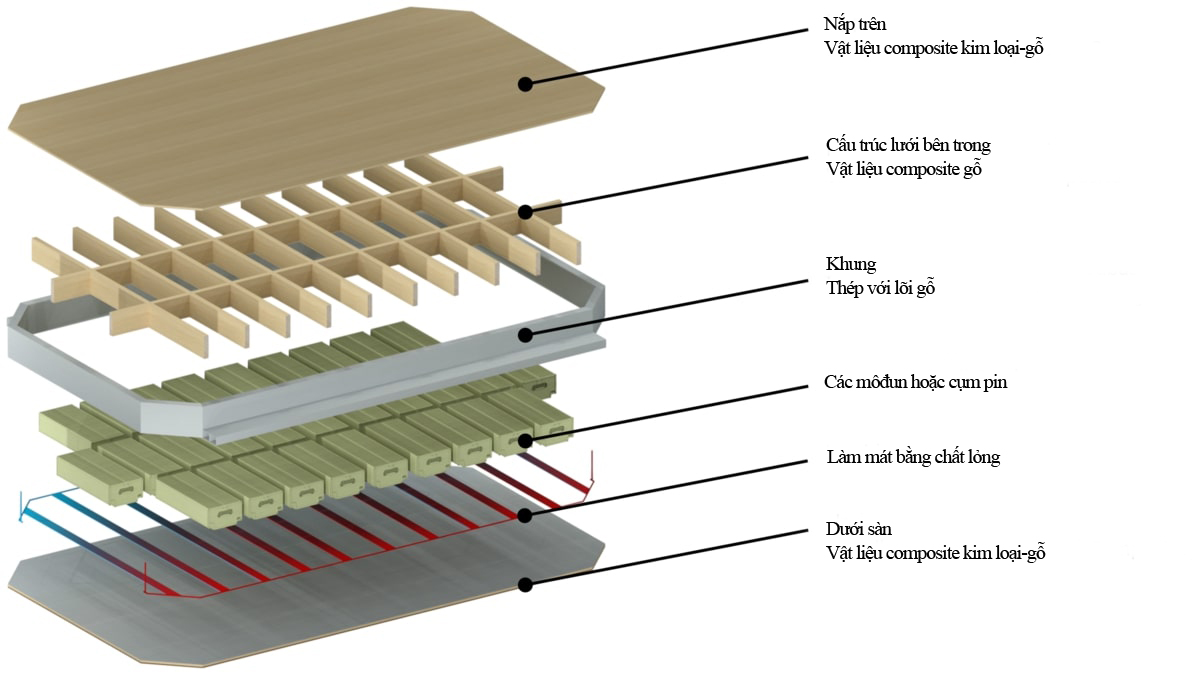

Structure of the battery pack casing made of steel and wood. Photo: TU Graz |

Structure of the battery pack casing made of steel and wood. Photo: TU Graz

The steel-wood hybrid battery casing demonstrated up to 98% higher energy absorption than ductile aluminum and 76% higher than high-strength aluminum under large deformations. All three wood versions exhibited good flexural strength.

By incorporating cork (wine bottle stopper)—another renewable material—the TU Graz team, led by Florian Feist, also enhanced the battery casing's fire resistance. This kept the temperature on the non-fire side 100 degrees Celsius lower than that of the Tesla battery casing.

"When exposed to very high temperatures, cork chars," Feist explained. "This charring process significantly reduces the already relatively low thermal conductivity, protecting the structures behind it."

TU Graz is also exploring methods to improve the reusability of the cork and the recyclability of components within the Bio!Lib casing. Furthermore, they are investigating the potential of using low-value wood, such as wood chips or recycled material, which could further enhance the design's environmental benefits.

As electric vehicles become increasingly prevalent, their environmental impact, extending beyond tailpipe emissions, is becoming clearer. While wood battery casings might seem unusual, studies like this demonstrate that smarter material choices can help electric vehicles better realize their clean energy potential.

My Anh (Energy-reporters)