Since its establishment in 1994, Panasonic Electric Works Vietnam (PEWVN) has implemented an in-depth business strategy, harmonizing Japanese technology with the local market. According to a company representative, this success is built on a solid foundation: the "five-factor design language."

This is more than just a design standard; it is a comprehensive, customer-centric system that governs every process, from market research and technology development to product planning, production, sales, and after-sales service. This philosophy ensures that every product reaching consumers embodies safety, reliability, convenience, aesthetics, and sustainability, aiming to create ideal living spaces and shape future lifestyles.

|

Panasonic's IAQ factory in Binh Duong, providing indoor air quality solutions. *Photo: PEWVN* |

To realize this philosophy, PEWVN transformed its Binh Duong factory into a "model factory," replicating the standard production process from the TSU factory in Mie, Japan, which produces 80 million wiring devices annually. The spirit of "Japanese quality" is evident in every detail, from precisely crafted metal molds and highly automated assembly lines to rigorous quality inspection processes. Each product must pass over 200 checks before leaving the factory, ensuring safety and reliability.

A prime example is the use of urea resin, a premium material with superior fire resistance and heat dissipation, for switches and sockets. "This choice not only minimizes fire risks but also provides impressive durability, capable of operating over 100,000 on/off cycles, equivalent to about 50 years of normal use," a PEWVN representative said.

To ensure a 100% perfect output, the company integrates artificial intelligence (AI) and digitalization into its quality control process, enhancing user confidence.

|

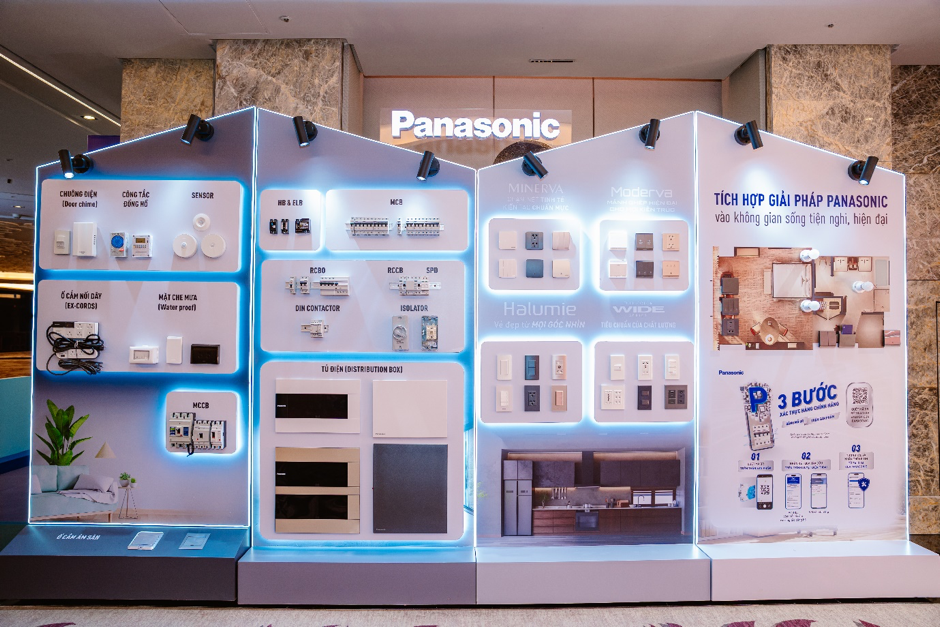

PEWVN's building electrical equipment solutions provide reliability, safety, and convenience for living spaces. *Photo: PEWVN* |

The "convenience" factor within the "five-factor" philosophy is fostered by PEWVN's deep understanding of local needs. Rather than imposing global products, the company established its research and development (R&D) department directly at the factory. This enables engineers to quickly grasp and respond to the specific demands of Vietnamese users. According to the roadmap, the indoor air quality (IAQ) factory will design "tailor-made" products for the Vietnam market starting in 2026. Meanwhile, the electrical construction materials (ECM) factory, after completing phase 3, will focus on independently developing new products with leading regional personnel.

Alongside these elements, "sustainability" is an indispensable component. As a group member, PEWVN actively supports the global "Panasonic Green Impact" strategy, aiming to reduce 300 million tons of CO2 emissions by 2050. In Vietnam, a more specific and ambitious goal has been set: to achieve Net Zero manufacturing status for its factory by fiscal year 2027. To accomplish this, the company is investing in solar energy systems while promoting a circular economy and comprehensive energy management in production.

These sustainable values are also extended into the community through practical activities such as reforestation, environmental protection, and strategic partnerships with universities, thereby developing high-quality human resources for the future.

From a modest representative office in 1994, PEWVN has expanded into three core areas: electrical construction materials (ECM), indoor air quality (IAQ), and lighting (LTG). With two large-scale factories, over 1,500 employees, and revenue exceeding 4,000 billion VND in fiscal year 2024, the company affirms its leading position in Vietnam.

"The foundation of the 'five-factor' philosophy enables Panasonic not just to sell products but also to create new living standards—where safety, convenience, and sustainability merge, fully winning the trust of Vietnamese consumers," the representative emphasized.

Panasonic Electric Works Vietnam is a member of the Panasonic group of companies in Vietnam. The company is a leader in manufacturing and trading building electrical equipment (sockets, switches, circuit breakers), fans, indoor air quality solutions, home appliances, lighting, and some business electrical equipment in Vietnam. Its products rank among the market leaders in both quality and sales volume.

(Source: Panasonic Electric Works Vietnam)