The facility, located in Industrial Park 5, Xuan Truc commune, Hung Yen, is expected to commence operations in 2027. The factory aims to enhance production capacity for liquid probiotic spores, meeting demand across various markets while ensuring quality control as the company expands its scale.

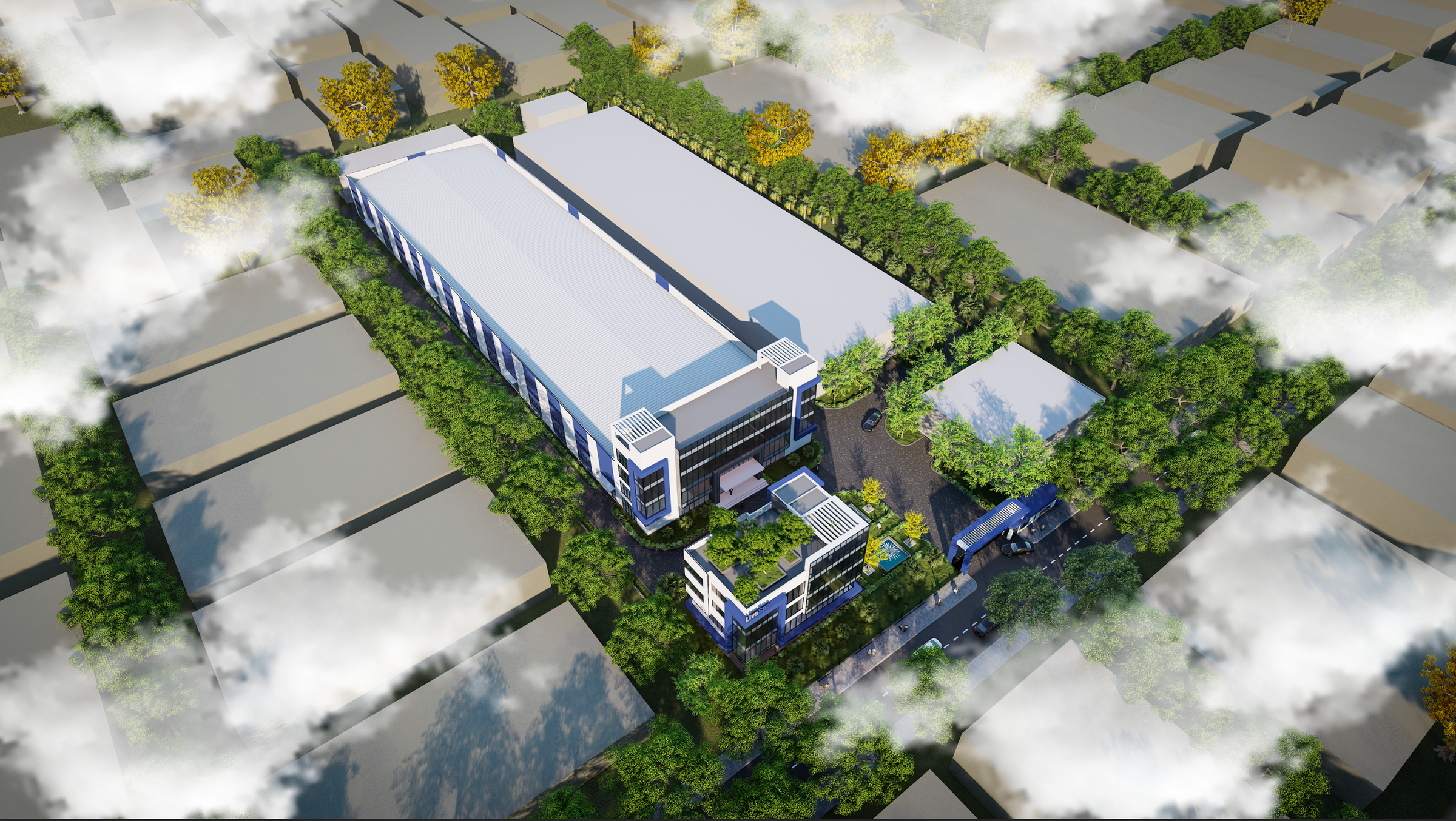

The entire factory complex will feature many functional areas, including: workshops; warehouses; auxiliary production buildings; an office building; a security room; a combined parking facility and canteen with a break area; a wastewater treatment system; and a fire protection system.

|

An aerial perspective of the factory, spanning nearly 16,000 m2. Photo: LiveSpo |

The new factory will enable expanded scale and increased capacity, integrating a series of sustainable development criteria in line with the EDGE green building standard, at level 2. Phase one, with an investment of 300 billion VND, commenced this December and is expected to complete the workshop, warehouse, office building, and associated auxiliary systems. The leadership views this phase as a crucial step, strengthening connection and synchronization between research, development, production, and quality control.

Speaking at the groundbreaking ceremony, Dr. Nguyen Hoa Anh, founder and chairman of LiveSpo Pharma Company Limited, reiterated the company's 15-year philosophy: "A future without antibiotics." According to him, this goal is challenging to achieve if limited solely to research and development. "We established a production foundation based on GMP standards in the previous phase. This investment aims to expand scale and elevate capacity to a higher level," he stated.

|

Dr. Nguyen Hoa Anh speaking at the factory's groundbreaking ceremony. Photo: LiveSpo |

Dr. Hoa Anh also noted that the company currently supplies liquid probiotic spores to many markets, necessitating a sufficiently large production system that meets all standards and is strictly controlled.

"In the fields of pharmaceuticals and health protection products, GMP serves as the foundation for ensuring production processes operate synchronously, with strict and transparent quality control. Building a factory to this standard allows us to actively control every stage," he explained.

For many years, LiveSpo has focused on systematic R&D (research and development), considering scientific foundation its core value. As product scale and market reach expand, the demand for production capacity grows. According to a company representative, investing in production infrastructure does not signify a change in direction but rather a necessary upgrade to consolidate and elevate standards for the next development phase.

"Phase one of the Hung Yen factory will serve current needs and create a premise for us to continue expanding and upgrading production capacity in the future, aiming for higher market standards," Dr. Hoa Anh analyzed.

|

The company's leadership performing the groundbreaking ritual for the new factory on 16/12. Photo: LiveSpo |

In the long term, the factory aligns with the roadmap to realize the mission of "A future without antibiotics" by increasing execution capacity and controlling the production system. "By combining scientific research with large-scale production, we hope to provide the community with valuable, sustainable healthcare solutions," Dr. Hoa Anh added.

LiveSpo specializes in researching and developing liquid probiotic spores for digestion, respiration, and other pathways, thereby balancing the microbiota and strengthening the first immune barrier to protect the body against attack from agents such as viruses and bacteria. A range of products has undergone independent clinical trials, registered with ClinicalTrials, and many studies have been peer-reviewed and published in Nature Portfolio.

Hieu Chau