Syre, an H&M subsidiary, chose Vietnam for its USD 1 billion recycling plant, a decision that is shaping the nation's advanced recycling economy, according to experts at the "Promoting Circular Economy in the Textile Industry" seminar held on december 18.

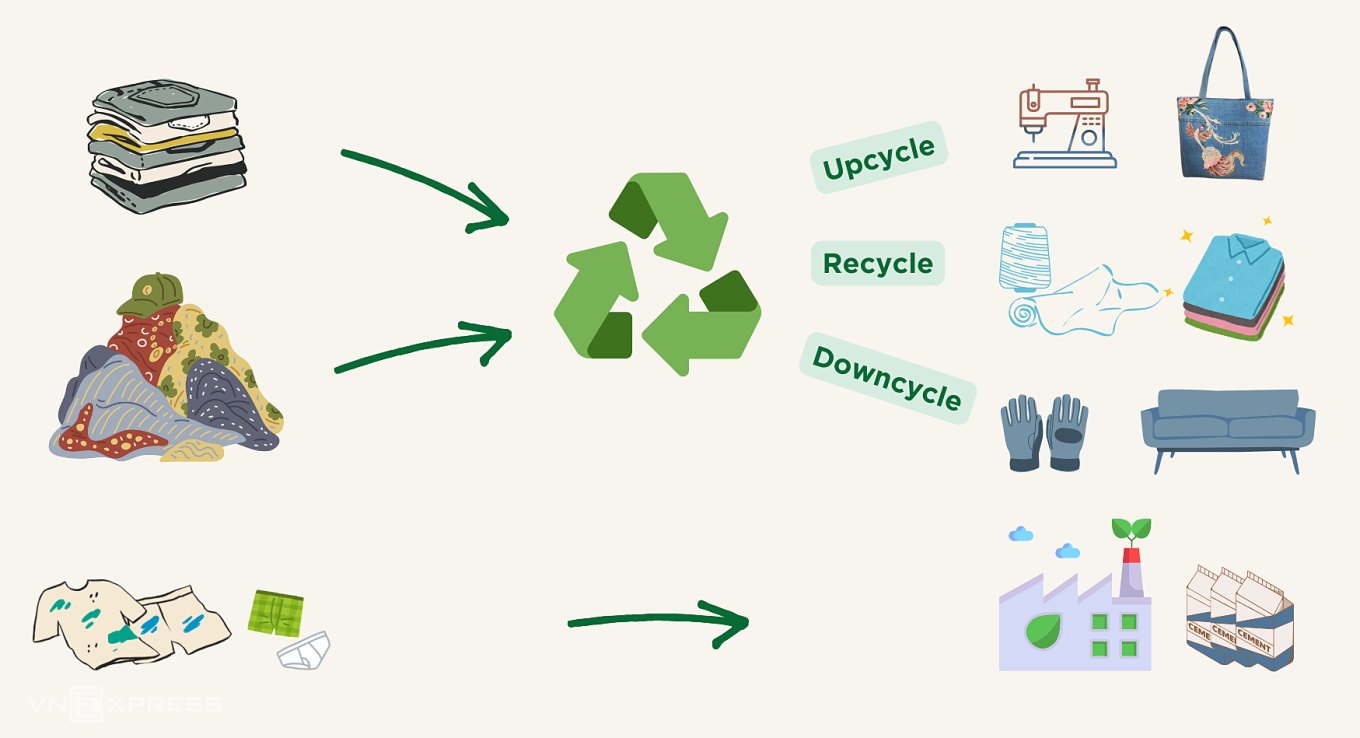

Advanced recycling employs new technologies, often chemical recycling, to create products of equivalent value to the original. This contrasts with down-cycling, a mechanical method that yields end products of lower value.

For instance, an old polyester shirt processed through advanced recycling technology can be converted into plastic pellets, which are then spun into yarn to create a new shirt. In down-cycling, the same shirt would be shredded and repurposed into items like cleaning rags or stuffing for plush toys and sofas.

|

Levels of textile waste recycling. Graphics: Bao Bao |

Phan Quynh Chi, a project officer at the German Agency for International Cooperation (GIZ) in Vietnam, noted that during the 2024-2025 period, "a new name joins" the advanced recycling sector every few months.

Beyond Syre, Vietnam has attracted numerous foreign businesses and startups in recent years, including Gr3n from Switzerland, Ambercycle from the US, Samsara Eco from Australia, Cure Technology from the Netherlands, and Saya Renew from Taiwan, China.

The emergence of these advanced foreign recyclers is creating pressure on domestic businesses, such as Tan Nam Trung, Vikohasan, and Hangbang, which primarily engage in down-cycling. A significant source of this pressure is the supply of raw materials.

According to a GIZ report from early this year, textile waste from factory production (pre-consumer waste) is estimated at 250,000 tons. Syre alone could absorb this entire volume if operating at full capacity by 2030. The company is currently collaborating with domestic partners to establish a waste collection and sorting system.

Furthermore, the increasing demand for recycled fibers from fashion brands is compelling these businesses to adapt and upgrade. Nguyen Mai Hanh, Head of Public Relations at Syre Group, stated that parent company H&M aims for 100% of the polyester fibers in its fashion products to be from recycled sources this year. They have signed a 7-year, USD 600 million long-term contract with Syre.

Inditex also targets 100% polyester from recycled fibers by 2025, while Uniqlo aims for 50% by 2030.

|

Socks woven from polyester fibers recycled from plastic bottles. Photo: Re.socks |

At the policy level, the European Union (EU), a major buyer of Vietnamese fashion products, mandates that most fashion goods must be made from recycled fibers by 2030. Businesses selling products in this bloc will also be subject to extended producer responsibility (EPR) from early 2025. This means they will be responsible for collecting used clothing and footwear, thereby creating a clean raw material source for the recycling industry.

A Syre representative believes this is a crucial moment for recycling businesses to seize opportunities arising from brand requirements and international partners. GIZ also recognizes Vietnam's growing importance to advanced recyclers, thanks to its abundant supply of textile waste, its key role in the global fashion supply chain, and favorable economic, political, and social factors.

Across the entire industry, Textile Exchange, a non-profit organization focused on climate in the fashion and textile sector, predicts a shift from the current linear development to a circular economy.

Typically, this economy extends from level one businesses (garment manufacturing), level two (fabric supply), level three (raw materials like fibers), to level 4 (raw material regions including cotton fields, oil wells). With a circular economy, level 3,5 businesses will emerge, comprising an ecosystem that supplies recycled fibers, returning raw materials to the supply chain.

In practice, Vietnam's textile industry is gradually forming a circular roadmap. A GIZ survey in september indicated that businesses have integrated recycled fiber content, controlled banned substances in production, and implemented order-based traceability to comply with EU ecodesign regulations, which are expected to take effect in late 2027.

Truong Van Cam, Vice Chairman and General Secretary of the Vietnam Textile and Apparel Association, noted that Vietnam currently has nearly 17,000 businesses in the textile industry, with 93% being small and medium-sized enterprises. In the field of recycled and sustainable materials, Vietnamese businesses have successfully produced fabrics from coffee fibers, lotus fibers, oyster shells (Faslink), pineapple leaves (Ecosoi), jute (An Phuoc), and even plastic bottles (Soi Vu Gia).

However, the "circular" transition is challenging without "economic" sustainability, which requires skilled human resources and business profitability. He recommended vertical policies from the government and ministries down to local authorities. Concurrently, horizontal development from associations and businesses, combined with support from international organizations, will help the textile industry achieve its circular goals.

Thuy Truong